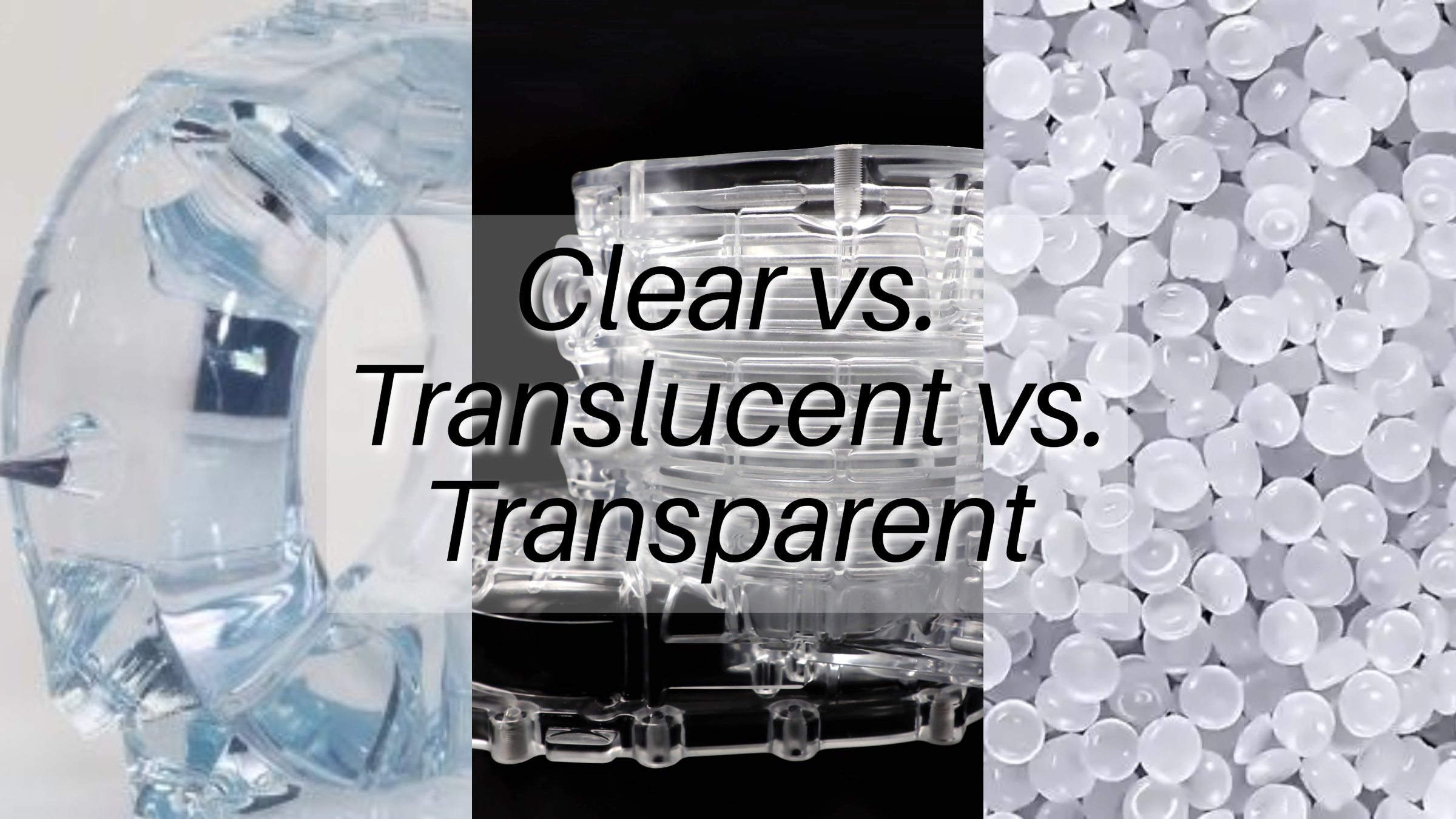

Clear vs. Translucent vs. Transparent: How to Distinguish

This article clarifies clear, translucent and transparent materials based on how they affect lighting.

Introduction

Clear, translucent, and transparent describe how materials transmit light. Understanding how each transmits light is important for optimizing material choice to meet the design's intended lighting, privacy, and visibility needs.

Clear vs. Translucent vs. Transparent: Differentiating Factors

Clear | Translucent | Transparent | |

|---|---|---|---|

Optical Properties | Allows light through clearly | Scatters light slightly | Allows light through clearly |

Light Transmission Levels | High, minimal distortion | Moderate, significant distortion | High, minimal distortion |

Visual Appearance | Optically pure, minimal distortion | Semi-opaque, some diffusion | Optically pure, minimal distortion |

Similarities between clear and transparent

The words "clear" and "transparent" are often used interchangeably in everyday language to describe materials like glass, plastic, and liquids.

Going forward, we will only refer to materials as 'transparent' if they transmit light with minimal diffusion, to avoid confusion from the common but imprecise use of 'clear'.

In this article, we will focus on explaining the difference between 'transparent' materials, which allow light to pass through directly, and 'translucent' materials, which scatter light and provide diffusion.

Optical Properties

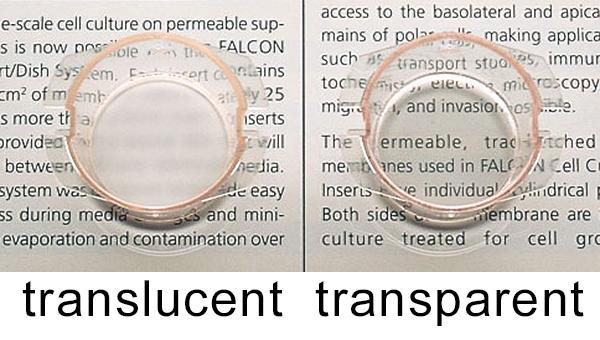

Clear & Transparent: Think regular glass or acrylic. They allow light through without scattering, giving a crisp view. For instance, clear glass windows offer an unobstructed view outside.

Translucent: Like frosted glass or wax paper, they let light through but scatter it, causing a blurred view. Frosted glass in bathroom windows allows light while providing privacy.

Light Transmission Levels

Clear & Transparent: High transmission with minimal distortion, around 92% for clear acrylic.

Translucent: Moderate transmission with noticeable diffusion, like frosted glass transmitting 70-80% of light.

Visual Appearance and Perception

Clear & Transparent: Optically pure, offering a direct view with minimal distortion, maintaining true colors and shapes.

Translucent: Semi-opaque, allowing some light through but diffusing it, creating a blurred appearance.

Source: Twitter: The_YUNiversity

Translucent vs. Transparent: Pros and Cons

Translucent | Transparent | |

|---|---|---|

Pros | Diffused lighting | Clear visibility |

Partial privacy | High light transmission | |

Concealment of imperfections | Minimal distortion | |

Cons | Reduced visibility | Lack of privacy |

Lower light transmission | Vulnerable to scratches | |

Limited application | Glare |

Translucent

Source: Unionfab

Pros:

Diffused lighting: Translucent materials scatter light, creating a soft and diffused lighting effect, which is desirable for creating ambient and comfortable environments.

Partial privacy: Translucent materials allow some light to pass through while partially obscuring objects, offering a degree of privacy without completely blocking visibility.

Concealment of imperfections: The diffusion of light in translucent materials can help conceal minor imperfections, enhancing aesthetic appeal.

Cons:

Reduced visibility: Clarity is lower as objects are obscured when viewed through translucent surfaces.

Transparent (Clear)

Source: Unionfab

Pros:

Clear visibility: Objects behind transparent materials can be seen with high clarity and no obstruction.

High light transmission: They allow a significant amount of light to pass through for bright, well-lit spaces.

Minimal distortion: Colors and shapes are maintained accurately when viewed through transparent surfaces.

Cons:

Lack of privacy: They do not provide any visual privacy due to clear viewing.

Vulnerability to scratches: Transparent materials are susceptible to scratches and may require regular maintenance to preserve their clarity and appearance.

Glare: In environments with intense sunlight, transparent materials can cause glare, affecting visibility and comfort levels.

Translucent vs. Transparent: Applications

Architecture and Design

Translucent: Used in decorative panels, privacy screens, and diffused lighting applications.

Transparent: Employed in architectural glazing, display cases, and high-end furniture.

Packaging and Labeling

Translucent: Utilized in frosted or tinted packaging for aesthetic appeal and partial visibility of contents.

Transparent: Found in clear containers and bottles for showcasing contents while maintaining product visibility.

Optical Devices and Technologies

Translucent: Employed in light diffusers, privacy filters, and lampshades for controlled light diffusion.

Transparent: Found in display screens, touch panels, and optical sensors for clear visibility and accurate light transmission.

Translucent vs. Transparent: Common Materials

Category | Material | Description | Applications |

|---|---|---|---|

Translucent | Tough, partial transmission | Automotive, electronics, appliances | |

Clarity, partial transmission | Packaging, signage, medical devices | ||

Biodegradable, varying translucency | 3D printing, packaging, tableware | ||

Transparent | High-temp clarity | Industrial, aerospace, lighting | |

Additive manufacturing, clarity | Prototypes, jewelry, product development | ||

Liquid polymer, transparent, casting | Casting, molding, jewelry, art, models |

Translucent Materials

ABS (Acrylonitrile Butadiene Styrene): ABS is a cost-effective thermoplastic polymer widely used in Fused Deposition Modeling and Injection Molding due to its ease of machining and production

PETG (Polyethylene Terephthalate Glycol): PETG is a durable and safe plastic, modified from PET with Glycol, offering improved rigidity and ease of use for 3D printing and machining.

PLA (Polylactic Acid): PLA is a widely used 3D printing material preferred for its low-temperature printing and lack of need for a heated bed.

Transparent Materials

High Temp 150 °C: High-Temp 150℃ is a red, transparent resin suitable for high-resolution models with exceptional heat resistance up to 150℃, ideal for industries like baking paint, electroplating, and rapid mold production.

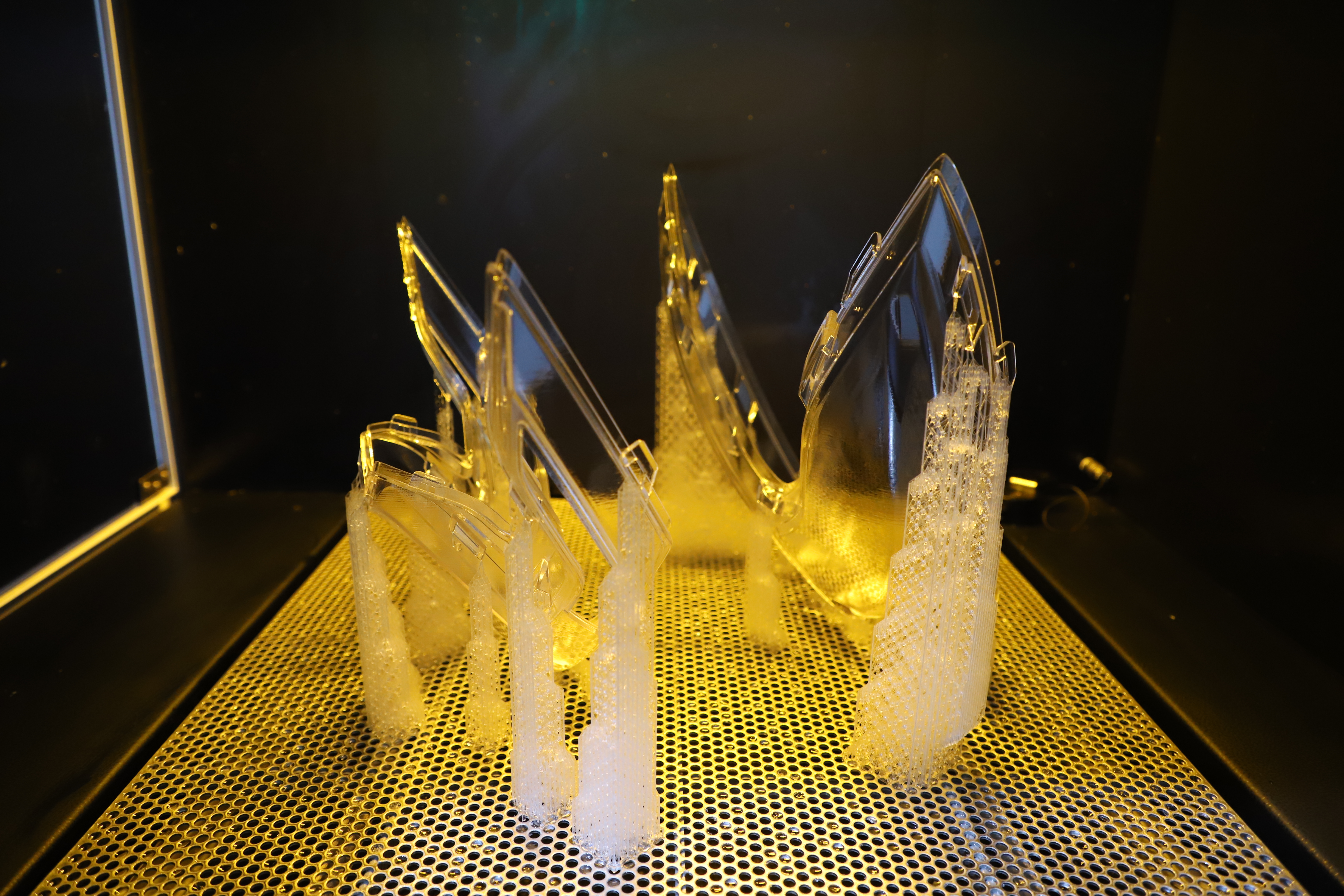

Source: Unionfab

Transparent Clear Resin: Formulated for additive manufacturing, offering exceptional clarity and surface finish for prototypes and jewelry.

Source: Unionfab

Casting Resin: Somos® WaterShed XC 11122 is a versatile, clear material favored for its detailed, durable, and water-resistant properties, resembling clear thermoplastics like ABS and PBT, making it ideal for designers and engineers alike.

Source: Unionfab

Conclusion

Understanding the differences between clear, translucent, and transparent materials is crucial for industries like architecture and packaging.

Clear materials offer visibility but lack privacy, translucent materials provide diffused lighting and partial privacy, and transparent materials offer clear visibility but are susceptible to scratches.

Explore Various Materials with Unionfab

Unionfab is a leading 3D printing and manufacturing company offering high-quality solutions tailored to various industries.

Our services cover a range of materials, such as standard resin (white), ABS, PETG and casting resin crucial for applications requiring translucent or transparent properties.

Get an instant quote now to start your transparent project!

For further information, please don't hesitate to reach out to us via our Contact Us page.